When it comes to critical fastening needs, manufacturers rely on a dependable provider that understands the importance of reliability. As a leading precision fastener solutions, we are dedicated to delivering an exceptional range of fasteners that meet the most demanding standards. Our comprehensive inventory encompasses a wide variety of types of fasteners, ensuring you with the perfect solution for your specific application.

- Our team are committed to providing customers with:

- Superior customer service and technical support

- Efficient lead times and on-time delivery

- Competitive pricing without compromising on quality

Premium Fasteners for Every Industry

Every industry requires fasteners that can withstand the toughest conditions. Whether you're in manufacturing, you need fasteners that are reliable, durable, and capable of performing flawlessly. That's why our company offers a wide variety of superior quality fasteners designed to meet the unique requirements of your industry. From nuts, to washers, we have the perfect fastener for your application. Our fasteners are made from premium materials and produced with precision to ensure exceptional strength, corrosion resistance, and longevity.

Choose our fasteners and experience the difference that quality delivers. We guarantee your satisfaction.

Robust Fastener Manufacturing Expertise

We are industry leaders in providing premium fastener manufacturing solutions. Our team of expert engineers and technicians utilize the latest equipment to ensure every fastener we produce meets exacting quality standards. We are committed to providing fasteners that are durable and can withstand even the most rigorous applications.

- Our a proven track record of reliably manufacturing fasteners for a diverse range of industries.

- We specialize in custom fastener design and production to meet your specific requirements.

- Choose us as your trusted partner for all your fastener needs. Contact us today to learn more about our capabilities.

Your Reliable

We understand that timely delivery and superior quality are crucial to your success. That's why we strive to be your trusted partner in fastener supply, offering a comprehensive range of products to meet every your needs. From standard fasteners to specialized solutions, our team is dedicated to provide the right components for your project, on time and within budget.

Through our extensive network of suppliers and robust logistics system, we ensure prompt delivery to your doorstep. We are committed to building lasting connections with our clients based on dependability and outstanding customer service.

Specialized Fastener Design and Fabrication

In a world where accuracy is paramount, engineers often require fasteners that go beyond conventional offerings. This is where custom fastener design and fabrication come into play. By partnering with experienced engineers and expert technicians, businesses can develop unique fasteners tailored to their specific application needs. Whether it's a intricate assembly or a high-stress environment, custom fasteners ensure optimal performance and reliability. The process typically involves analyzing the load requirements, material properties, and environmental conditions to choose the most appropriate design and fabrication methods.

- Frequent materials used in custom fastener fabrication include steel, stainless steel, aluminum, brass, and plastic.

- Sophisticated manufacturing techniques such as CNC machining, forging, and 3D printing are often employed to produce the desired form and functionality.

- The result is a fastener that not only fulfills the technical specifications but also optimizes the overall performance of the end product.

Bolts, Screws, Nuts: Your One-Stop Shop

Need to fasten parts together? Look no further! Our extensive selection of bolts, screws, nuts has you covered. Whether you're working on a major construction undertaking, we have the perfect hardware to get the job done. Our highly qualified staff read more is always available with your concerns. We offer a selection of sizes, types, and materials to satisfy all your requirements.

- Durable fasteners

- Competitive prices

- Quick shipping options

High-Performance Fasteners for Demanding Applications

In demanding applications, where reliability and durability are paramount, high-performance fasteners play a critical role. These specialized fasteners are engineered to withstand extreme stress levels, ensuring optimal performance. Constructed from premium compounds, they offer exceptional toughness and resistance to corrosion, wear, and tear. From aerospace and defense to oil and gas, high-performance fasteners provide the necessary resilience for critical components in a wide range of industries.

Fasteners that Stand the Test of Time

When it comes to construction, infrastructure, or any application demanding reliability, fasteners are the unsung heroes. These tiny components often shoulder the weight of our world, literally and figuratively. To ensure projects remain the test of time, choosing the appropriate fasteners is paramount.

Factors like material composition, durability against rust, and design are vital in determining a fastener's lifespan. High-grade materials such as stainless steel or titanium offer exceptional robustness and resisting harsh conditions.

- {Moreover,Beyond that, meticulous installation practices are critical for maximizing fastener performance.

- Proper tightening torque, thread lubrication, and surface preparation all contribute to a secure and lasting bond.

Investing in quality fasteners is a wise decision that remunerates dividends over the long haul. They guarantee structural integrity, minimize maintenance costs, and ultimately contribute to the longevity of any project.

Cutting-edge Fastener Technologies

The fastener industry is experiencing rapid advancements, driven by the need for lighter fastening solutions. This evolution has led to the emergence of advanced fastener technologies that deliver a comprehensive selection of benefits.

Among these innovations are:

* Expanding fasteners: These fasteners reduce the need for pre-drilling, saving time and effort.

* Magnetic Fasteners: Utilizing piezoelectricity for secure attachment, these fasteners provide a innovative to traditional mechanical methods.

* Adaptive Fasteners: Equipped with intelligent technology, these fasteners can respond to changing environments, providing dynamic feedback and improved efficiency.

The future for fastener technologies is bright. As research continues, we can expect to see even more revolutionary advances that fulfill the ever-evolving needs of various industries.

Meeting Global Fastener Standards adhere

In today's worldwide marketplace, achieving global fastener standards is critical for businesses. These specifications guarantee that fasteners operate reliably and securely in a spectrum of applications. Meeting with these standards can improve a company's standing, enable global trade, and decrease the risk of claims.

- A key aspect of meeting global fastener standards involves understanding the requirements set forth by organizations such as the The ISO.

- Manufacturers must implement quality control systems to confirm that their fasteners conform with these standards.

- Regular audits and evaluation are also essential for maintain compliance.

Engineering Excellence

The fastener manufacturing industry demands strict quality control and a commitment to state-of-the-art engineering principles. To achieve optimal performance, manufacturers must harness the latest technologies and adopt best practices throughout the production process. From material selection to final inspection, every step requires finesse to ensure that fasteners meet the demanding requirements of various industries.

A key aspect of engineering excellence is the continuous improvement of manufacturing processes. By embracing advancements, manufacturers can enhance efficiency, reduce costs, and ultimately deliver fasteners that surpass industry standards.

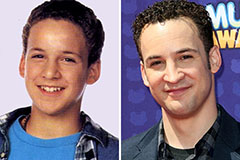

Ben Savage Then & Now!

Ben Savage Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!